Filigree: The Timeless Craft and How It’s Made

Filigree—from the Latin filum (thread) and granum (grain)—is one of the oldest and most revered jewellery-making techniques, tracing back over 3,000 years. This delicate art involves twisting fine metal wires into intricate, lace-like patterns, forming designs that seem almost woven from light.

From the ornamental treasures of Mesopotamia and Egypt to the refined goldwork of ancient Greece, filigree has adorned the artefacts of great civilisations. In medieval Ireland, it reached new heights in masterpieces like the Ardagh Chalice and Tara Brooch, where sacred symbolism met unmatched craftsmanship.

Today, filigree remains a living tradition—a dialogue between past and present—embodying both technical mastery and cultural memory in every wire-thin thread.

At Pusaka Jewellery, we honour the enduring art of filigree—an intricate metalworking tradition passed down through generations. Each piece is meticulously handcrafted, ensuring that this centuries-old craft not only survives but thrives in the modern world.

Our name, Pusaka—meaning “treasure” or “heirloom” in Indonesian—embodies our commitment to timeless craftsmanship, cultural storytelling, and the beauty of handmade imperfection.

Founded by multi-award-winning jewellery designer Edwin Charmain, our London-based studio bridges heritage and innovation. Drawing deeply from Edwin’s Indonesian textile lineage, each design is both a homage to the past and a contemporary artefact—made to be worn, cherished, and passed down.

A Dialogue Between Metal and Memory

Filigree is more than a decorative technique—it is a meditative, slow craft that demands both mastery and patience. At Pusaka, we practise this discipline through a process rooted in traditional methods. Every curve and coil tells a story—shaped by hand, guided by history.

Below is a glimpse into the traditional process used to create each Pusaka piece:

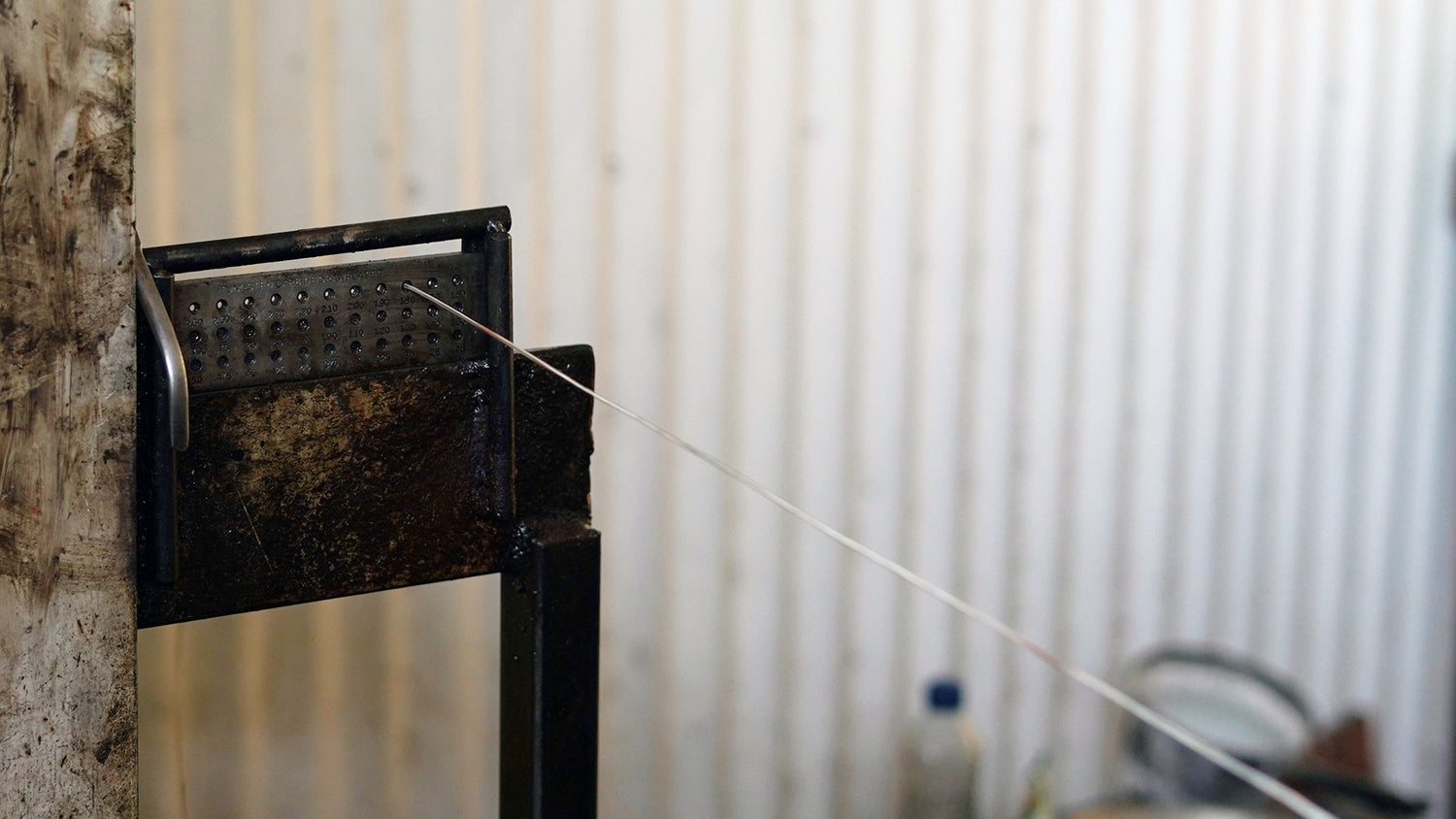

Step 01

Preparing the Metal

We begin with smelting precious metal—usually fine silver or gold—melted, rolled, and drawn into precise wires with the help of draw plate.

Through repeated annealing and shaping, the wire is softened and refined to achieve the flexibility essential for intricate work.

Step 02

Spinning The Filigree Wire

Two or more ultra-fine wires are gently twisted into rope-like strands, then lightly flattened through a rolling mill to create a subtle ribbon effect—a signature texture of filigree's visual language.

Step 03

Creating the Frame

A sturdier wire is shaped into the outer form of the piece—this frame becomes the structural foundation, housing the filigree’s delicate interior motifs.

Step 04

Forming the Filigree Patterns

Using age-old techniques, the fine wire is curled into tendrils, spirals, and coils—arranged with precision into the frame to achieve balance, fluidity, and symbolic depth.

Step 05

Soldering the Components

With care and controlled heat, each wire is fused into place. The process demands steady hands and exact timing—too much heat risks collapse, too little and the piece won’t hold.

Step 06

Cleaning and Refining

The piece is immersed in a gentle pickling solution to remove oxidation, then polished to enhance brilliance and refine the surface without losing the texture of the maker’s touch.

Step 07

Adding Surface Treatments (Optional)

Depending on the design, the piece may be oxidised, plated, enameled, or textured to highlight contrast and dimension—revealing the layered depth of its construction.

Step 08

Final Polishing and Quality Check

Every detail is inspected and polished by hand. Only when the piece meets our exacting standards of craftsmanship is it ready to be worn—carrying with it the story of its making.

Filigree is not just adornment—it is a quiet resistance against disposability. A labour of love. A connection between hands, history, and heart.

Whether a delicate earring, a sculptural ring, or an ornate heirloom piece, every Pusaka creation embodies a timeless elegance—made to carry meaning across lifetimes.